Drones in Oil Rig Inspections: Ensuring Safety

In the dynamic and high-risk environment of oil rig inspections, safety is paramount. The integration of cutting-edge technology has significantly transformed the inspection processes, with drones emerging as a game-changer. These unmanned aerial vehicles (UAVs) offer a safer, more efficient, and cost-effective alternative to traditional inspection methods. In this article, we will explore the role of drones in oil rig inspections and how they contribute to ensuring safety in this critical industry.

1.Enhancing Safety Through Remote Inspections:

Oil rigs are complex structures located in challenging environments, often offshore or in remote areas. Conducting inspections on these structures can be hazardous for human workers due to harsh weather conditions, height, and other environmental factors. Drones, equipped with advanced cameras and sensors, allow for remote inspections, eliminating the need for human presence in high-risk areas. This not only reduces the potential for accidents but also enhances overall safety.

2.Efficiency and Speed in Inspections:

Traditional inspection methods on oil rigs can be time-consuming, requiring extensive planning and resources. Drones offer a rapid and efficient alternative, covering large areas in a fraction of the time it would take a human inspection team. The quick turnaround not only minimises downtime but also allows for more frequent inspections, ensuring that potential issues are identified and addressed promptly, further contributing to safety protocols.

3.Advanced Imaging Technology for Precise Analysis:

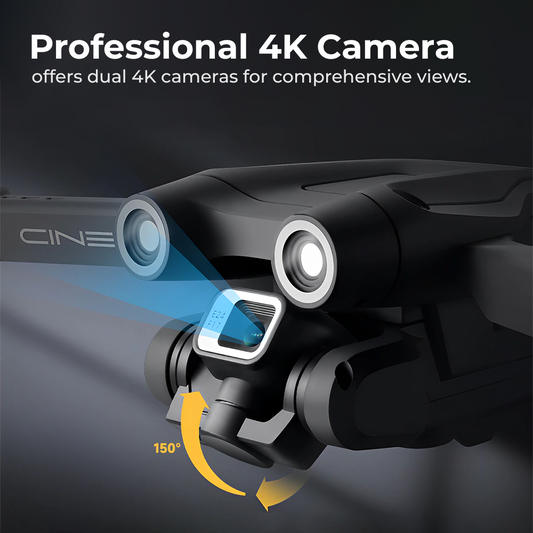

Drones are equipped with high-resolution cameras and sensors that capture detailed images and data. This technology allows inspectors to detect even minor defects or anomalies that may go unnoticed with the naked eye. The precise analysis provided by drones ensures that potential safety hazards are identified early on, preventing them from escalating into more significant issues that could compromise the integrity of the oil rig.

4.Real-time Monitoring and Data Analysis:

Drones offer real-time monitoring capabilities, allowing inspectors to receive live feeds of the inspection. This instantaneous data transmission facilitates on-the-spot decision-making and a quicker response to emerging issues. Additionally, the data collected during inspections can be analysed to identify patterns or trends, enabling proactive maintenance and safety measures. The ability to gather and analyse data in real-time is a crucial aspect of ensuring the ongoing safety of oil rig operations.

5.Cost-effectiveness and Resource Optimization:

Traditional inspection methods often require significant resources, including manpower, equipment, and time. Drones provide a cost-effective alternative by reducing the need for extensive human involvement and specialised equipment. The efficiency and speed of drone inspections contribute to overall cost savings, allowing companies to allocate resources more strategically for enhanced safety measures and continuous improvements.

6.Reducing Environmental Impact:

The use of drones in oil rig inspections aligns with the growing emphasis on environmental sustainability. Traditional inspection methods, such as helicopter flyovers, can contribute to carbon emissions and environmental disruption. Drones, being smaller and more agile, have a significantly lower environmental impact. This aligns with the industry's commitment to reducing its carbon footprint while ensuring the safety and integrity of oil rig operations.

7.Regulatory Compliance and Safety Standards:

The oil and gas industry operates under strict regulatory frameworks and safety standards. Drones can play a crucial role in ensuring compliance with these regulations by providing accurate and comprehensive data for inspection reports. The detailed information gathered by drones assists companies in demonstrating adherence to safety standards, thereby avoiding potential legal and financial repercussions.

8.Training and Skill Development:

Implementing drone technology in oil rig inspections also opens up opportunities for skill development among the workforce. Training personnel to operate and manage drones enhances their technical skills and knowledge, contributing to a more versatile and skilled workforce. As the industry evolves, having personnel with expertise in drone technology ensures a seamless integration of these innovative tools into the inspection processes, further enhancing safety measures.

9.Challenges and Solutions:

While the adoption of drones in oil rig inspections brings numerous benefits, it is essential to address potential challenges. These may include technical issues, regulatory hurdles, and concerns related to data security. Companies investing in drone technology must implement robust training programs, regularly update equipment, and stay abreast of evolving regulations to ensure a smooth and secure integration.

Drones have revolutionised the landscape of oil rig inspections, offering a safer, more efficient, and cost-effective solution. By leveraging advanced imaging technology, real-time monitoring, and data analysis, companies can enhance safety protocols, comply with regulatory standards, and optimise resources. As the industry continues to evolve, embracing drone technology is not just a choice but a necessity for ensuring the safety and sustainability of oil rig operations. The marriage of innovation and safety through drones is a testament to the industry's commitment to progress and its responsibility towards both its workforce and the environment.

Explore a variety of drones at our online drone store.

Happy Flying!