The Benefits of Drones in Hydroelectric Dam Inspections

In the realm of infrastructure and energy, hydroelectric dams stand as colossal guardians of power generation. These engineering marvels, however, demand vigilant care to ensure their optimal functionality and longevity. Traditional inspection methods often prove laborious, time-consuming, and sometimes risky. Enter drones – a revolutionary technology that is transforming the landscape of hydroelectric dam inspections. In this article, we delve into the myriad benefits that drones bring to the table, enhancing the efficiency, safety, and precision of dam inspections.

1.Rapid and Comprehensive Inspections

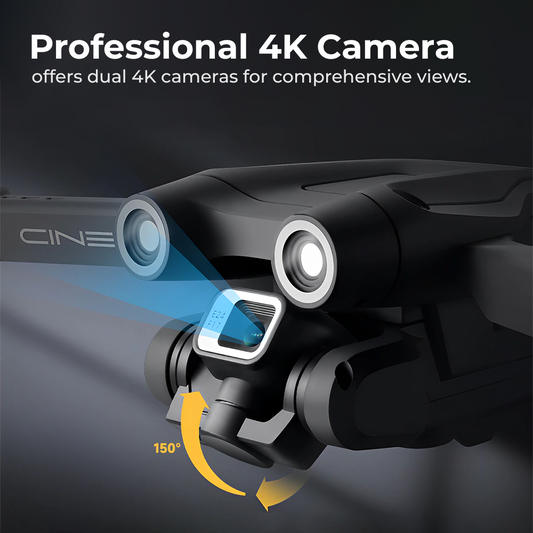

Drones, equipped with high-resolution cameras and advanced sensors, offer an unparalleled ability to swiftly and comprehensively inspect hydroelectric dams. The nimble aerial devices can cover vast areas in a fraction of the time it would take human inspectors. This speed not only reduces downtime but also allows for more frequent inspections, ensuring that potential issues are identified and addressed promptly.

2.Enhanced Safety for Inspection Crews

One of the most significant advantages of using drones in dam inspections is the enhanced safety for inspection crews. Traditional methods often involve manual inspections, exposing workers to hazardous conditions and heights. Drones eliminate the need for human presence in precarious situations, mitigating the risk of accidents and injuries. With drones taking on the role of inspectors, human resources can be allocated to more strategic and less perilous tasks.

3.Cost-Effective Solutions

Drone-based inspections offer a cost-effective alternative to traditional methods. The reduced need for human labour, heavy equipment, and extensive downtime contributes to significant cost savings. Drones can access difficult-to-reach areas without the need for scaffolding or specialised equipment, further cutting down on expenses. In the long run, the investment in drone technology pays off through increased efficiency and minimising operational costs.

4.Real-Time Data Acquisition

Drones are equipped with advanced imaging technology that enables real-time data acquisition during inspections. High-resolution cameras and sensors capture detailed images and measurements, providing inspectors with immediate insights into the dam's condition. This real-time data allows for quick decision-making, as potential issues can be identified on the spot, minimising the risk of unforeseen complications.

5.Precision and Accuracy

The precision of drone technology is a game-changer in dam inspections. Drones can navigate intricate structures and capture detailed images with remarkable accuracy. This precision is particularly crucial in identifying early signs of wear, tear, or structural damage that may go unnoticed with traditional inspection methods. The ability to pinpoint issues with precision ensures that maintenance efforts are targeted and effective.

6.Environmental Impact

Reducing the environmental footprint is a growing concern in every industry, and dam inspections are no exception. Traditional inspection methods, involving heavy machinery and manual labour, can have adverse effects on the surrounding ecosystem. Drones, being lightweight and agile, minimise environmental impact. They can traverse the dam and its surroundings without disrupting the natural habitat, aligning with sustainable practices in the energy sector.

7.Data Analytics for Predictive Maintenance

The data collected by drones is not merely a snapshot of the dam's current state; it serves as a foundation for predictive maintenance strategies. Advanced analytics can be applied to the amassed data, identifying patterns and trends that may indicate potential future issues. This proactive approach allows for timely interventions, preventing major damages and extending the lifespan of the hydroelectric dam.

8.Minimise Disruption to Operations

Traditional inspections often necessitate shutdowns or reduced operational capacities, causing disruptions in power generation. Drones, with their rapid deployment and non-intrusive nature, minimise these disruptions. Inspections can be conducted without affecting the dam's regular operations, ensuring a continuous and stable power supply to the grid.

9.Regulatory Compliance and Documentation

In the highly regulated field of energy production, compliance with industry standards and regulations is paramount. Drones facilitate the documentation of inspections in a meticulous and standardised manner. The recorded data and imagery provide a comprehensive visual history of the dam's condition, aiding in regulatory compliance and serving as valuable documentation for future assessments.

10.Training and Skill Development

The integration of drone technology in dam inspections opens up avenues for skill development and training. Operators and inspectors can acquire expertise in drone operation and data analysis, contributing to a more skilled workforce in the energy sector. This not only benefits the industry but also provides career growth opportunities for professionals involved in dam maintenance.

The benefits of using drones in hydroelectric dam inspections are multifaceted, ranging from increased efficiency and safety to cost savings and environmental sustainability. As technology continues to advance, the integration of drones into infrastructure maintenance practices becomes not just a choice but a necessity. Embracing these unmanned aerial systems ensures that our hydroelectric dams, the backbone of power generation, continue to operate optimally, safeguarding our energy future.

Explore a variety of drones at our online drone store.

Happy Flying!